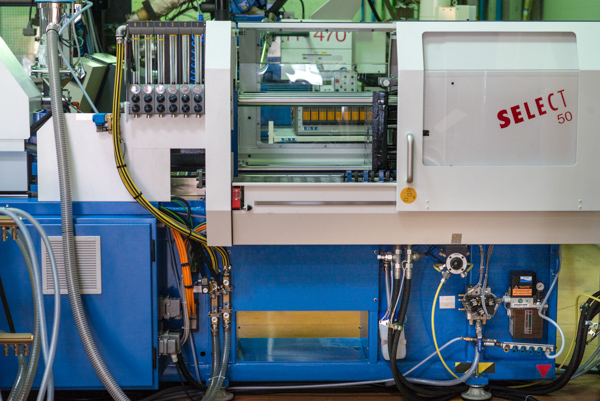

Comprising bi-injection presses of between 50 and 320 tonnes, our machinery stands out for its flexibility and versatility. It allows all types of tests to be carried out and fulfils your mono or bi-injection production requirements.

The presses are:

fitted with 3-axis digital robots

electric and hydraulic

fitted with large trays and have an injection capacity which is suitable for all product volumes

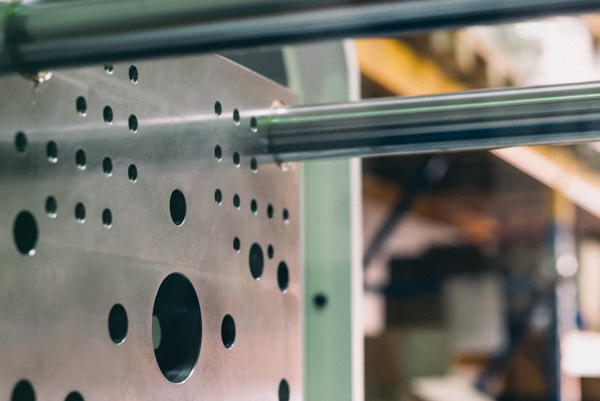

capable of handling up to six hydraulic cores to fulfil the kinematic requirements of complex moulds.

fitted with a rotating base for the use of a rotary bi-injection mould.

-> See also : PÉRIPHÉRIQUES.