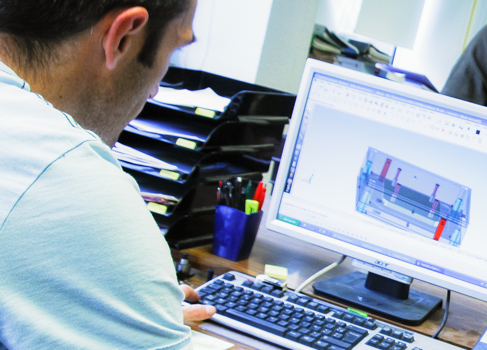

Our core business, known and recognised in the market for innovation and for successfully managing the most complex projects, the skills and services of our design office provide:

management of your project from mould design to the mass production of the pieces

the industrialisation of all means of production

optimisation of multi-component products

The implementation of lean management, the expertise of our multidisciplinary teams comprising materials and plastics specialists and engineers and the support of our laboratory enable us to respond efficiently to the specifications of clients. With its proactive approach, Ixemer provides tailor-made solutions, taking account of:

financial constraints

the financial requirements

and by producing:

Technical and financial feasibility studies

Technical studies: scaling, optimisation, etc.

Functional prototypes

Analysis of pieces and/or sub-assemblies made from plastic materials

Completion of the prototype stages

Definition of the specifications for non-plastic components and supplier selection

Monitoring of the design and production of the injection moulds

Design and manufacture of specialised machines for implementation

The fine-tuning of fabrication moulds in partnership with our test centre

The production of the required metrology and tests for acceptance of the pieces up to the submission of the initial samples

” The greatness of a profession is above all uniting human beings “

Saint Exupéry